High Water Pressure 210D Waterproof Oxford Cloth – Durable PU Coated Fabric for Agricultural Irrigation & Inflatable Arches

It happened again just before dawn—a sharp hiss cutting through the morning silence, followed by a spray of water erupting from a ruptured irrigation belt. Li Wei, a cotton grower in Xinjiang, stood knee-deep in mud, watching months of careful planning drip away into the soil. The culprit? A common polyester fabric that couldn’t withstand the relentless push of high-pressure irrigation. This isn’t just one farmer’s frustration; it’s a recurring story across fields where traditional materials buckle under stress, forcing replanting delays, wasted water, and mounting costs. What if there were a fabric built not just to resist water—but to command it?

Inside the Unbreakable: The Science Behind 210D Oxford Cloth

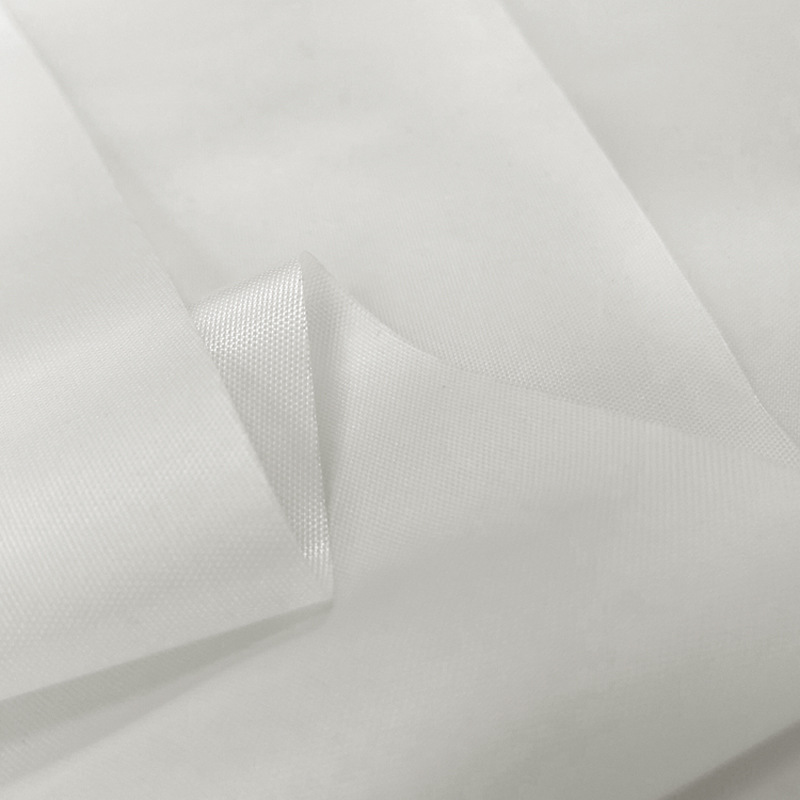

The number “210D” isn’t marketing fluff—it’s a promise etched in thread count and tensile strength. Denier (D) measures the thickness of individual fibers, and 210D signifies a robust filament that forms the backbone of this Oxford cloth. When woven in a tight basket-weave pattern, the result is a fabric that distributes force evenly, resisting punctures and tears that plague lighter alternatives. Under magnification, the difference is striking: standard polyester shows loose gaps between threads, while 210D Oxford interlocks like armor plating, creating a lattice so dense that pressure waves travel smoothly—without weak points.

PU Coating: The Invisible Shield Against Nature’s Assault

But strength alone isn’t enough. Water finds every flaw, every microscopic opening. That’s where the polyurethane (PU) coating steps in—not as a surface layer, but as a molecular sealant that penetrates and encapsulates each fiber. Imagine a rainstorm pounding down on an uncoated fabric: water seeps through capillary action, weakening bonds over time. Now picture the same storm hitting PU-coated 210D Oxford. Droplets bead and roll off like mercury, leaving the interior bone-dry. Beyond waterproofing, this coating resists UV degradation, chemical runoff, and microbial growth—critical for long-term deployment in sun-scorched fields or muddy terrains.

One Fabric, Two Lives: From Farm Fields to Festival Arches

In the agricultural world, this material has redefined reliability. As the core component of modern sprinkler belts, it maintains uniform water pressure across kilometers of farmland, eliminating the burst zones that once plagued irrigation networks. But its journey doesn’t end at the edge of the field. Designers have taken note. Lightweight yet structurally sound, the same fabric now breathes life into inflatable arches at weddings, music festivals, and public art installations. Its ability to hold air under variable wind loads—while remaining flexible enough for rapid inflation—makes it ideal for temporary structures that demand both drama and durability.

Battle-Tested in the Real World

The true test of any material lies in extreme environments. In Xinjiang’s cotton belt, a single irrigation line made from this 210D fabric operated 12 hours daily for six consecutive months—zero leaks, no structural fatigue. In the steep, uneven梯田 of Southwest China, where hoses twist and bend with terrain shifts, the fabric resisted kinking and retained integrity despite constant mechanical stress. And during a sudden thunderstorm at an open-air music festival, an inflatable sculpture made from the same cloth endured gusts over 60 km/h and heavy rainfall without deflating or sagging—proof that performance transcends application.

Reading the Fabric’s Story Through Touch and Sight

Quality speaks silently. Run your fingers over a genuine PU-coated 210D Oxford cloth: the surface should feel smooth but not greasy, with no tackiness that signals poor curing. Bend it sharply—the coating must flex without cracking or showing white stress marks. Examine the cut edges: tightly packed yarns with minimal fraying indicate precision manufacturing. These aren’t cosmetic details—they’re fingerprints of longevity.

Where Agriculture Meets Architecture

It started with a phone call. A landscape architect in Chengdu was designing a pop-up pavilion for a riverside park and needed something lightweight, weather-resistant, and fast to assemble. After exhausting conventional options, she turned to agricultural suppliers—and found her answer in irrigation-grade Oxford cloth. Today, that same material shelters visitors from sun and rain in modular urban installations. It’s a quiet revolution: when two disciplines converge, they reveal shared needs—resilience, adaptability, efficiency—and a single fabric rises to meet them all.

Under Pressure, It Performs

Return to that broken irrigation belt in Li Wei’s field. Replace it with today’s 210D PU-coated Oxford solution. The numbers tell the story: maintenance cycles extended from weeks to seasons, water loss reduced by over 90%, and labor hours saved add up to real profit. This isn’t incremental improvement. It’s a recalibration of what we expect from outdoor textiles. Whether channeling water through arid fields or shaping air into celebration, this fabric proves that under the highest pressure, true quality doesn’t just survive—it thrives.